Steam power has played a transformative role in shaping modern industry and technology. From the early days of the Industrial Revolution to contemporary power generation, steam engines and steam turbines have been fundamental in harnessing the energy of steam. Both technologies utilize steam to generate mechanical work, but they do so through distinct mechanisms and applications. This blog aims to clarify the differences between steam engines and steam turbines, exploring their operational principles, historical significance, and current uses. By examining these technologies, we can better understand their unique contributions and how they continue to impact various industries.

Basics of Steam Power

At its core, steam power operates on the principle of converting thermal energy into mechanical work. When water is heated, it turns into steam, which expands and creates pressure. This pressure can then be harnessed to perform work. Both steam engines and steam turbines utilize this principle, but in different ways. Steam engines use steam pressure to create reciprocating motion, while steam turbines convert steam into rotary motion. These fundamental principles underlie their respective operational mechanisms and applications.

Steam Engines

Steam engines function through a reciprocating mechanism. In a steam engine, steam enters a cylinder and pushes a piston back and forth. This reciprocating motion is then converted into rotational motion through a crankshaft. The key components of a steam engine include cylinders, pistons, and valves, which control the flow of steam. Steam engines were developed during the 18th century and had a profound impact on the Industrial Revolution. They powered early locomotives, steamships, and industrial machinery, significantly enhancing transportation and manufacturing processes.

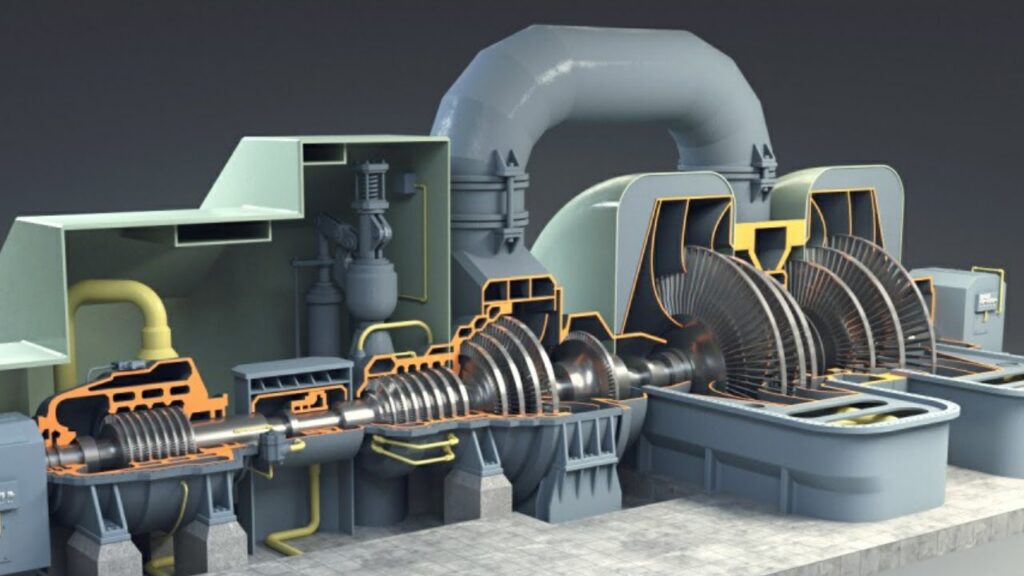

Steam Turbines

In contrast, steam turbines operate using a rotary mechanism. Steam is directed over blades mounted on a rotor, causing the rotor to spin and generate rotational motion. The main components of a steam turbine include rotor blades, a stator that directs steam flow, and nozzles that control steam entry. Developed in the late 19th century, steam turbines quickly became integral to modern power generation. Their ability to handle high pressures and deliver consistent, efficient power made them essential for large-scale electricity production and industrial applications.

The gas turbine Control system keeps an eye on things and protects you from dangerous situations. Turbine control systems for power plants are made by companies like GE and Woodward. IS200VSCAH2ABA, IS200EGPAG1BEC, and IS200EPSMG1AED are examples of GE turbine control spare parts. The control software package is used to program, configure, trend, and analyse diagnostics on Mark VIe controllers and related systems.

Differences Between Steam Engines and Steam Turbines

The primary difference between steam engines and steam turbines lies in their operational mechanisms. Steam engines utilize reciprocating motion, while steam turbines employ rotary motion. This difference affects their efficiency and performance. Steam engines generally have lower efficiency due to friction and the complexity of converting motion. In contrast, steam turbines are more efficient, with higher energy conversion rates and the capability for continuous operation. Additionally, steam engines are suited for smaller-scale and historical applications, whereas steam turbines are ideal for large-scale power generation and industrial processes. Maintenance and operational complexity also vary, with steam engines requiring more maintenance due to their moving parts compared to the generally lower-maintenance steam turbines.

Historical and Modern Impact

Steam engines had a monumental impact on transportation and early industrialization, driving advancements in railways, steamships, and manufacturing. They marked a significant shift in productivity and economic growth during the Industrial Revolution. On the other hand, steam turbines have played a crucial role in modern energy production. Their efficiency and reliability have supported the expansion of power grids and industrial capacities, facilitating the development of modern infrastructure and energy systems.

Case Studies and Examples

Notable steam engines include the Watt Engine, developed by James Watt, which greatly improved efficiency and was used in various applications during the Industrial Revolution. Another significant example is the Stephenson Locomotive, or “Locomotion No. 1,” which revolutionized rail transport. In the realm of steam turbines, the Parsons Turbine, created by Charles Parsons, was one of the first successful turbines used in power generation. Modern examples include the General Electric (GE) Steam Turbine, which showcases advanced efficiency and technology in contemporary power plants.

Future Trends and Innovations

While modern adaptations of steam engines are rare, they continue to be used in niche applications such as educational demonstrations and historical restorations. Steam turbines, however, are the focus of ongoing advancements. Innovations in materials and design are enhancing their efficiency, and developments in combined-cycle power plants are improving performance. Additionally, integrating steam turbines with renewable energy sources is increasing their sustainability and relevance in a more environmentally conscious energy landscape.

Summary

Steam engines and steam turbines both utilize steam to generate power, but they do so through distinct mechanisms. Steam engines operate on the principle of reciprocating motion, converting steam pressure into linear motion, which was revolutionary for transportation and early industrial processes. In contrast, steam turbines use a rotating motion to convert steam energy into mechanical power, making them highly efficient for large-scale power generation and industrial applications. While steam engines played a crucial role in the industrial revolution, steam turbines have become the preferred choice for modern energy production due to their efficiency and capacity for continuous operation. Understanding these differences highlights how technological advancements have transformed energy production and industrial efficiency over time.

Also Read: Top Tips for Finding the Best Deals on Crashed Vehicles for Sale

Профессиональный сервисный центр по ремонту бытовой техники с выездом на дом.

Мы предлагаем:сервисные центры по ремонту техники в мск

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

¡Hola aficionados a las apuestas !

Los 100 giros gratis sin depГіsito EspaГ±a te permiten conocer los juegos sin arriesgar. Es la mejor forma de familiarizarte con el casino antes de jugar en serio. ВЎSolo para nuevos jugadores!

Bono de 100 giros gratis sin depГіsito PokerStars 2025 – 100 giros gratis sin depósito pokerstars.

¡Que tengas magníficas triunfos !

¡Hola expertos del azar !

Explora juegos y gana en grande.

Descubre todo lo que puedes ganar con 25 giros gratis sin depГіsito y sorprГ©ndete.

¡Que tengas magníficas rondas inolvidables !

¡Hola, apasionados de los juegos !

Aprovecha las promociones de bonos sin depГіsito para descubrir juegos nuevos sin arriesgar tu dinero.

Para acceder al bono de 10 euros gratis sin depГіsito solo necesitas registrarte y seguir unos pasos simples. No hay necesidad de introducir mГ©todos de pago. Una vez cumplidos los requisitos, el bono estarГЎ listo para usarse.

Casino online te da 10 euros gratis sin depГіsito – https://www.youtube.com/@squeezer007

¡Que tengas excelentes instantes de fortuna!

Профессиональный сервисный центр по ремонту техники в Йошкар-Оле.

Мы предлагаем: Сколько стоит ремонт видеокарт Manli

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

Предлагаем услуги профессиональных инженеров офицальной мастерской.

Еслли вы искали срочный ремонт холодильников gorenje, можете посмотреть на сайте: ремонт холодильников gorenje сервис

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

¡Hola, amantes del ocio y la suerte !

Los bonos no se eliminan si no los usas en 24h. Tienes tiempo para decidir. casas de apuestas no reguladas

Casas de apuestas sin licencia para jugadores que valoran la privacidad – п»їhttps://apuestas-sin-licencia.net/

ВїNo sabes quГ© juego elegir? Algunas plataformas te dan recomendaciones personalizadas segГєn tu historial de juego.

¡Que disfrutes de beneficios extraordinarios !

¡Hola, exploradores de oportunidades !

Casinos fuera de espaГ±a permiten crear cuentas mГєltiples con diferentes mГ©todos de pago sin restricciones.Esto da mГЎs control al usuario sobre su banca y movimientos.TambiГ©n facilita separar juegos y presupuestos.

casino fuera de espaГ±a

Casino por fuera con bonos de bienvenida exclusivos – п»їhttps://casinoporfuera.xyz/

¡Que disfrutes de jugadas increíbles

Hola, aventureros del juego !

El casino por fuera de EspaГ±a cuenta con juegos exclusivos que no se encuentran en plataformas reguladas. casinosonlinefuera Los casinos fuera de EspaГ±a suelen actualizar sus promociones con mayor frecuencia. Casinosonlinefuera.xyz facilita el acceso sin necesidad de descarga de software.

Casinosonlinefuera.xyz: plataformas СЃ licencia internacional – п»їhttps://casinosonlinefuera.xyz/

Los casinos fuera de EspaГ±a tienen catГЎlogos con miles de juegos, desde clГЎsicos hasta novedades. En casinos online fuera de EspaГ±a, los torneos con premios en NFT son cada vez mГЎs comunes. Casinosonlinefuera.xyz permite jugar sin lГmites de tiempo ni validaciones molestas.

¡Que disfrutes de fantásticas giros afortunados !

¡Saludos, cazadores de premios!

Esta variedad incluye slots asiГЎticas, ruleta europea o blackjack americano. La experiencia se vuelve verdaderamente global.

Casino online extranjero con versiГіn mГіvil y cashback – https://www.casinos-extranjeros.es/#

Los mejores casinos online extranjeros integran herramientas de control de pГ©rdidas automГЎticas. Esto ayuda a mantener el juego bajo control sin esfuerzo. Seguridad emocional y econГіmica.

¡Que disfrutes de increíbles jugadas magistrales !

¡Saludos, aventureros del riesgo !

Casinos no regulados sin comprobaciГіn de identidad – https://casinossinlicenciaenespana.es/# casinos sin licencia

¡Que vivas oportunidades exclusivas !

¡Hola, cazadores de tesoros!

Casinos online extranjeros para jugar sin datos personales – https://www.casinoextranjerosespana.es/# casino online extranjero

¡Que disfrutes de asombrosas movidas brillantes !

¡Hola, amantes de la emoción !

Casino sin registro con retiros inmediatos – https://casinossinlicenciaespana.es/ casino sin licencia espaГ±a

¡Que experimentes éxitos destacados !

¡Hola, participantes del desafío !

Top casino fuera de EspaГ±a con bonos sin depГіsito – https://www.casinoonlinefueradeespanol.xyz/ casinoonlinefueradeespanol

¡Que disfrutes de asombrosas momentos memorables !

¡Saludos, jugadores dedicados !

Top 10 de casinos online extranjeros que aceptan jugadores – https://casinoextranjerosenespana.es/# casino online extranjero

¡Que disfrutes de momentos inolvidables !

¡Saludos, apostadores entusiastas !

Mejores botes progresivos en casinos extranjeros – https://casinosextranjero.es/# casinos extranjeros

¡Que vivas increíbles instantes inolvidables !

¡Bienvenidos, entusiastas del azar !

Casino fuera de EspaГ±a con experiencia fluida y legal – https://www.casinoporfuera.guru/ casino por fuera

¡Que disfrutes de maravillosas momentos memorables !

¡Hola, fanáticos del riesgo !

Juegos de cartas en casinos extranjeros recomendados – https://www.casinoextranjero.es/# casino online extranjero

¡Que vivas jugadas asombrosas !

¡Saludos, descubridores de tesoros!

casinos fuera de EspaГ±a con bonos festivos – п»їhttps://casinosonlinefueraespanol.xyz/ casinosonlinefueraespanol

¡Que disfrutes de jackpots fascinantes!

¡Hola, amantes del ocio y la emoción !

Casino online extranjero con retiro rГЎpido garantizado – https://www.casinosextranjerosdeespana.es/# п»їcasinos online extranjeros

¡Que vivas increíbles jackpots sorprendentes!

¡Bienvenidos, apostadores apasionados !

Casino fuera de EspaГ±a con juegos de proveedores top – https://casinofueraespanol.xyz/# casinofueraespanol.xyz

¡Que vivas increíbles conquistas brillantes !

¡Saludos, amantes del entretenimiento y la adrenalina !

Casinos online extranjeros sin documentos ni esperas – https://www.casinoextranjerosdeespana.es/ casinos extranjeros

¡Que experimentes maravillosas premios excepcionales !

?Hola, visitantes de plataformas de apuestas !

Casino por fuera con bonos por recarga – п»їhttps://casinosonlinefueradeespanol.xyz/ casinos online fuera de espaГ±a

?Que disfrutes de asombrosas logros notables !

Hello navigators of purification !

Best Air Purifier for Smokers – Durable Units – https://bestairpurifierforcigarettesmoke.guru/# smoke purifier

May you experience remarkable invigorating spaces !

¡Hola, seguidores del entretenimiento !

Casino sin licencia espaГ±ola con bonificaciones frecuentes – http://casinosinlicenciaespana.xyz/ casino online sin registro

¡Que vivas increíbles jugadas brillantes !

¡Bienvenidos, seguidores de la emoción !

Casinos sin registro y sin comisiones – https://mejores-casinosespana.es/# п»їcasinos sin licencia en espaГ±a

¡Que experimentes maravillosas triunfos legendarios !

¡Saludos, apasionados del ocio y la emoción !

Casino sin licencia en EspaГ±a sin comprobantes – https://emausong.es/# casino sin licencia espaГ±ola

¡Que disfrutes de increíbles victorias épicas !

¡Hola, buscadores de premios excepcionales!

Casino sin licencia con acceso libre – http://www.casinosonlinesinlicencia.es/ casinos sin licencia en espana

¡Que vivas increíbles recompensas extraordinarias !

¡Saludos, fanáticos del desafío !

Casinos con bono de bienvenida en euros – https://bono.sindepositoespana.guru/ casino bono bienvenida

¡Que disfrutes de asombrosas premios excepcionales !

Greetings, adventurers of hilarious moments !

Adult jokes that make you blush and laugh – п»їhttps://jokesforadults.guru/ great adult jokes

May you enjoy incredible unique witticisms !

Greetings, contenders in humor quests !

dad jokes for adults are perfect for casual bonding. Everyone laughs—even if they don’t want to. That’s their magic.

joke for adults only is always a reliable source of laughter in every situation. adultjokesclean.guru They lighten even the dullest conversations. You’ll be glad you remembered it.

real dad jokes for adults That Go Too Far – п»їhttps://adultjokesclean.guru/ short jokes for adults

May you enjoy incredible unexpected punchlines!

Hello lovers of clean ambiance !

The best air purifiers for pets often feature odor indicators so you know when extra filtration is needed. For people working from home, an air purifier for dog hair improves air clarity in home offices and helps focus. Installing the best air purifier for pet hair by your sofa minimizes buildup on upholstery.

The best air filters for pets include allergy-friendly certification, ensuring they meet medical-grade air quality standards.best air purifier for pet allergiesTop rated air purifiers for pets often come with sleep modes for silent overnight operation. Investing in the best air purifier for pet allergies protects children, the elderly, and anyone with respiratory sensitivities.

Best Air.Purifier for Pets with HEPA and Carbon Filter Combo – п»їhttps://www.youtube.com/watch?v=dPE254fvKgQ

May you enjoy remarkable refreshed spaces !

¿Saludos amantes del azar

En los casinos europeos online puedes elegir mГ©todos de pago modernos como Skrill, Neteller o incluso criptomonedas. Esto da flexibilidad y anonimato a quienes prefieren evitar bancos tradicionales. casinosonlineeuropeos.guru La innovaciГіn financiera es una ventaja clara.

Muchos consideran que los mejores casinos en lГnea estГЎn en Europa debido a sus normativas estrictas. Los jugadores valoran especialmente la seguridad que ofrecen los casinos europeos al manejar datos personales y bancarios. Esta regiГіn es lГder en innovaciГіn dentro del juego digital.

Casino europeo con autenticaciГіn biomГ©trica – п»їhttps://casinosonlineeuropeos.guru/

¡Que disfrutes de grandes beneficios !

Часто читаю и слежу за выходом новостей на tellmi.ru.

Хотите быть в курсе событий? Читайте актуальные события в России и мире – тут

Envio mis saludos a todos los creadores de fortuna !

Los casinos sin licencia en EspaГ±a ofrecen seguridad con cifrado avanzado. No dependen de la regulaciГіn local para proteger datos. Un casino sin licencia en EspaГ±a garantiza anonimato y confianza.

Un casino sin licencia en EspaГ±a puede ser una alternativa interesante para quienes buscan anonimato total. Estos sitios permiten jugar sin verificaciones molestas ni papeleos. Por eso, cada vez mГЎs usuarios acceden a casinos sin licencia en EspaГ±a.

Juega en casinos sin licencia de forma segura – п»їhttps://casinoonlineeuropeo.blogspot.com/

Que disfrutes de increibles rondas !

casinosinlicenciaespana.blogspot.com