Hydraulic systems are essential in many industries, from manufacturing to creation, making sure that equipment operates smoothly and efficaciously. However, the hydraulic filter plays a essential role in keeping the health of these structures. Over time, hydraulic filters can emerge as clogged or broken, leading to decreased overall performance and potential system failures. In this article, we can discover the pinnacle symptoms that indicate your hydraulic filter out needs alternative and provide steering on the way to choose the satisfactory clear out on your wishes.

Decreased Hydraulic Performance

One of the first signs that your hydraulic filter may also want substitute is a substantial lower in overall performance. When the clear out turns into clogged with contaminants, the waft of hydraulic fluid is restricted, causing the machinery to paintings harder to acquire the preferred output. This can happen as slower operation speeds, reduced lifting potential, or erratic movements in hydraulic system. If you word any of those symptoms, it’s crucial to test the hydraulic clear out and update it if important. Regular tracking of equipment overall performance can help identify those adjustments early, stopping similarly harm and luxurious upkeep down the road.

Increased Operating Temperature

Another tremendous indicator of a failing hydraulic clear out is an growth in working temperature. When the hydraulic fluid encounters a clogged filter out, the pump have to paintings more difficult to circulate the fluid, which generates additional warmness. Elevated temperatures can cause thermal degradation of the hydraulic fluid, lowering its effectiveness and durability. If you observe a upward push in temperature readings for your hydraulic system, it can be time to inspect and potentially replace the hydraulic filter. Keeping an eye on temperature trends can help ensure your equipment operates within gold standard conditions, extending its lifespan and overall performance.

Fluid Contamination

Fluid contamination is a chief concern for any hydraulic gadget. If you note visible contaminants in the hydraulic fluid, including dust, metal shavings, or water, it’s a clean signal that your filter may be compromised. Over time, filters can grow to be saturated with particles, leading to leap forward infection that may damage critical components inside the hydraulic device. Conducting regular fluid evaluation can assist become aware of contamination problems early. If tests reveal excessive infection ranges, replacing the hydraulic filter out ought to be a pinnacle priority. Additionally, imposing a proactive preservation schedule can save you infection troubles from escalating, saving money and time in the end.

Filter Indicator Warning Light

Many cutting-edge hydraulic systems come prepared with filter indicator caution lighting that alert operators when the filter is nearing its ability. These lighting fixtures function a vital line of protection, allowing customers to cope with filter issues before they lead to full-size troubles. If the caution light turns on, it is essential to behave quickly through examining and changing the hydraulic filter out as essential. Ignoring those indicators can bring about reduced gadget efficiency, multiplied wear and tear, and potential system disasters. Familiarizing your self with the caution signs unique for your system can resource in effective preservation and activate action while troubles get up.

Frequent Filter Changes

If you locate yourself converting your hydraulic filter out greater regularly than anticipated, it may be a sign of underlying troubles with the system or the clear out itself. While filters do have a service existence, excessive clogging or infection can imply that the gadget is experiencing extra sizeable problems, inclusive of leaks or bad preservation practices. To decide if the common modifications are warranted, verify the operating environment and the satisfactory of hydraulic fluid being used. If the situations are especially harsh or the fluid best is subpar, recall upgrading to a stronger filter designed to deal with such demanding situations. Evaluating the reasons at the back of common changes can cause higher filtration alternatives and progressed universal device performance.

How to Choose the Best Hydraulic Filter

Choosing the proper hydraulic filter is important for preserving the fitness of your hydraulic system. Here are a few key elements to consider while choosing a hydraulic clear out:

Filter Type and Media

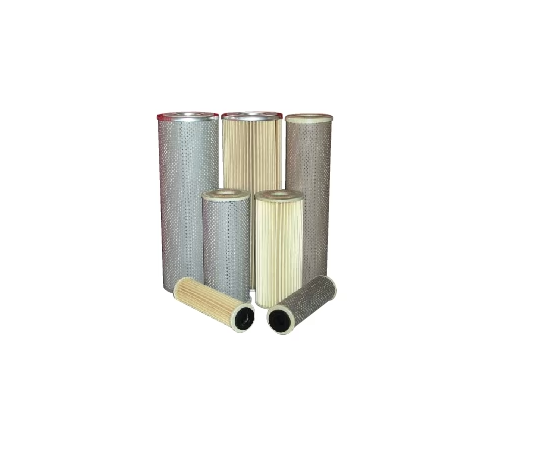

The first step in choosing the proper hydraulic filter is to determine the correct clear out type and media in your application. Hydraulic filters are available in diverse paperwork, together with suction, return, and strain filters, each designed for particular features within the machine. Additionally, clear out media options vary, consisting of paper, artificial, and cord mesh substances. Understanding the requirements of your hydraulic system and the contaminants you anticipate to come upon can help you pick the maximum appropriate filter out type and media.

Micron Rating

Micron rating indicates the clear out’s capability to capture particles of precise sizes. The lower the micron score, the smaller the debris the clear out can entice. Selecting a filter with the correct micron score is crucial for shielding your hydraulic gadget. A filter out with a micron score too low in your utility may limit fluid float, whilst one with a rating too excessive may additionally allow dangerous particles to bypass via. Consult your hydraulic gadget’s specs and discuss with specialists to decide the suitable micron score to your wishes.

Flow Rate

Ensuring that the hydraulic filter out can accommodate your system’s drift fee is crucial for optimal overall performance. Each clear out has a most drift price it can cope with, and exceeding this restrict can cause strain drops, reduced performance, and potential device failures. When deciding on a hydraulic filter, evaluate the manufacturer’s specifications to affirm that the filter out can aid your system’s glide necessities. Selecting a filter out with the proper glide fee will assist hold gadget efficiency and reliability.

Compatibility

It is essential to ensure that the hydraulic filter out you pick out is well suited together with your present hydraulic system. Check for compatibility in phrases of length, mounting configuration, and fluid type. Installing an incompatible filter out can cause leaks, device failures, or decreased overall performance. To avoid problems, seek advice from the hydraulic machine’s guide or paintings with a informed supplier to find a clear out that meets all compatibility necessities.

Manufacturer Reputation and Quality

Finally, keep in mind the popularity and great of the manufacturer when selecting a hydraulic filter. Investing in a extremely good filter from a reputable manufacturer can prevent time and money ultimately by lowering the frequency of replacements and making sure reliable performance. Look for filters that meet industry standards and have high quality reviews from different users. Researching and deciding on a reliable manufacturer will help ensure that you pick out the first-class hydraulic filter out on your device.

Conclusion

In conclusion, spotting the symptoms that your hydraulic filter out needs alternative is vital for maintaining the efficiency and longevity of your hydraulic structures. Regular monitoring of performance, temperature, fluid high-quality, and filter out indicators let you discover problems early and prevent high-priced repairs. When it comes time to select felt bags, do not forget factors which includes filter type, micron score, go with the flow rate, compatibility, and manufacturer reputation. By being proactive on your preservation and filter out choice, you could ensure that your hydraulic systems function at their exceptional for future years.

More Stories

Using a Virtual Office for Your GST Registration

Hellstar Hoodie has become an iconic piece in

Why Should Consider Buying Dog Supplements