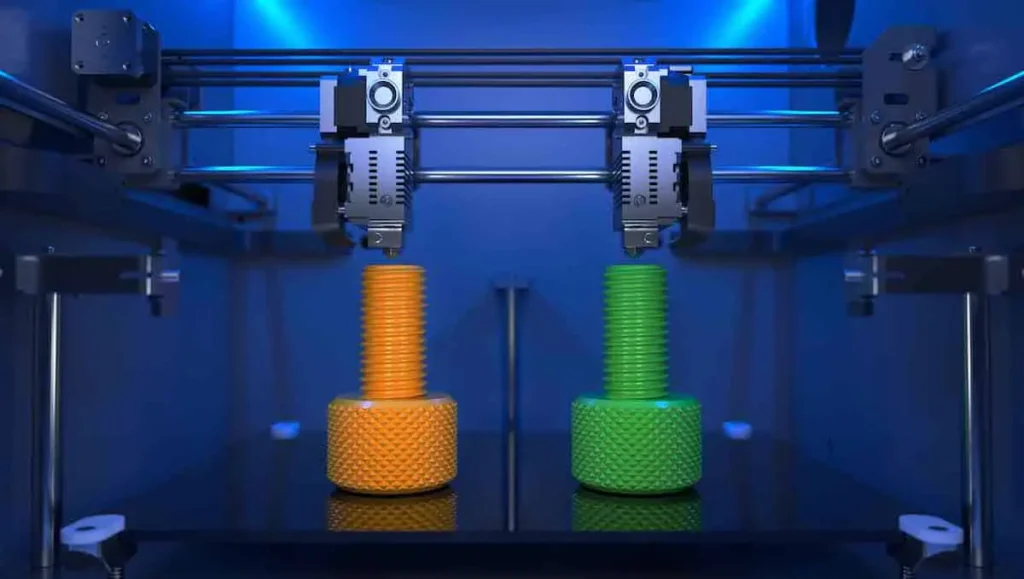

3D metal printing gas emerged as a game-changing advancement in technology. It totally modifies the era of the manufacturing industry. In addition, it offers exceptional precision and efficiency. On the other hand, this printing with customization transforms how we construct metal components and products. This blog helps you to learn the aspects that convert three-dimensional metal printing into a revolutionary category of industries. It also explains the various types of 3D metal printers and their uses.

What is 3D Metal Printing?

3D metal printing involves creating three-dimensional metal objects by adding layers of metal wire& powder. In addition, researchers have infused these powders and wires into the material from a high-energy source. They use electron beams and lasers for this purpose.

Dissimilar to conventional subtractive generating methods, this technique is applied to the object layer by layer. Consequently, the control application of chemicals and wires shows minimal material waste. Also, it allows researchers to attain complex geometrics that were previously impossible.

Pros of 3D Metal Printing

There are numerous advantages to using this stunning metal printing service. Let’s dive into detail to know.

Have Freedom for Flexible Designs

The major benefit of using this material is the freedom of flexible and customized designs. Therefore, if the purchaser wants intricate internal structures, engineers are able to create and optimize the performance. Also, they can print complex geometries on the metal to meet the consumer’s needs.

Ensure Material Efficiency

Experts use minimal metal wire and powder in metal printer design, and development reduces waste. Basically, the minimal use of resources not only decreases costs but also helps industries to fulfill the sustainability goal. The efforts to conserve raw materials help our planet stay sustainable.

Customization And Personalization

Three-dimensional metal printing advancements enable the creation of various unique parts to meet specific needs. Moreover, the tailored capability shines in industries like automotive, medical, and aerospace. Thus, custom-made elements are also mandatory for innovation and performance.

Rapid Production

This metal printing imperatively speeds up the generating and prototyping process. Experts can make changes to the product and improve them to refine the designs. Therefore, this metal printing simplifies the product process and removes the need for complicated molds and tools. So, the direct creation of desired geometrics on the metal is a free process.

Applications of 3D Printing in Various Industries

The application of 3D printing has a wide range of industries. Multiple firms benefit from this stunning printing type. In the aerospace industry, engineers encourage metal printing to generate lightweight and high-strength components.

For instance, they use them for structural components, engine parts, and intricate ducting systems. When they produce the part by optimizing geometrics, the results show appreciative weight savings. Similarly, It also assists in escalating the performance and fuel efficiency.

3D metal printing is also fruitful in the medical field and provides countless benefits. Also, this latest technology ensures the production of patient-specific implants that precisely match individuals’ needs.

Car makers are using this stunning metal printing to generate high-performing and lightweight parts. This technology helps engineers make complex engine parts and customizes them for interior pieces. It will help them to improve cars’ performance and make them more efficient.

Furthermore, it is revolutionizing the production of molds and tools. It can create adjustable cooling channels within the molds. These channels assist in efficient cooling and reducing cycle times. Besides, it improves the quality of the final product incredibly.

Type of Top-notch 3D Printers

Engineers use 3D printing on metals through different methods. Each of the materials has its qualities, which makes them perfect. Now, we learn about the various types of 3D metal printers that experts use for metal printing with three-dimensional effects. All the mentioned types of metal printers are used for different purposes.

XDM 120

The first printer is XDM 120, and engineers use this to build volumes 120x 120x 120 mm. Also, it provides benefits for highly detailed and intricate parts. Furthermore, it is accessible to educational institutions and small businesses. This printer is an affordable option with a high-performance rate.

In the jewelry industry, it is perfect for custom pieces with high detailing. It is also used in medicine to produce surgical tools. In the research and education sector, it is work for experimentation and teaching. Here are some key features of this printer.

- Up to 15 microns

- Metals suited for a fine ending

- Compact and user-friendly

- 150Wfiber laser

XDM 250

The XDM 250 is a potent tool for industries that want efficiency in a compact design. This printer is versatile and easy to use for any manufacturing setup. Furthermore, the build volume of the XDM 250 printer is 250x 250x 300mm.

For this reason, this printer is ideal for smaller production facilities and research labs. Also, it is excellent for intricate parts and reduces material waste. However, it is best for surgical tools and customized impulses in the medical field. Here are the key features:

- Up to 25 microns

- 250W fiber laser

- Simple operation with the latest control system

- Compatible with titanium, aluminum, and stainless steel

- Creation of lightweight and complex engine parts

- Produce precision aircraft parts

XDM 300

The build volume of XDM 300 is 300x 300x 300, and the layer resolution is up to 20 microns. Besides, this XDM300 metal printer is good for intricate designs and small components. Apart from this, XDM 300 is suitable for a wide range of applications and materials. The stunning printer is easily perfect for a small product environment. Some key features are here:

- Resolution up to 20 microns

- Laser power 300W

- Ideal for small-scale production

- Confirms detailed and high-quality prototypes

XDM 420

As the name shows, the build volume of this 3D printer for metal is 420x 420x 300m. The layer resolution is up to 25 microns. Therefore, it is helpful for detailed and accurate manufacturing needs. XDM 420 3D printer for metal is best for optimizing small-batch products and medium-sized parts.

- 350W fiber laser

- Titanium, stainless steel, and aluminum

- Real-time process of monitoring

- Produce smaller structural components

- Best for product custom tooling and parts for industries

XDM 500

Experts designed the XDM 500 3D printer to meet the needs of various industries that need efficiency and accuracy. It has a large build volume of 500x 500x 500mm, and layer resolution is up to 20 microns. However, this printer is best for large components or different small parts in one run to save resources. Also, it is ideal for delated and complex designs, and the key features are here for your information.

- 500W fiber laser

- Ensure efficient material use

- Automated powder handling system

- Ideal for complex designs and manufacturing aerospace parts

- Use for the product of large implants and surgical tool

XDM 750

Inventors create XDM 750 metal printers for industries that need high-capacity manufacturing solutions. The build volume of this printer is 750x 750x 500mm. In addition, the latest features make it the top option for large-scale productions. Furthermore, the material compatibility of this metal is good in a wide range, such as aluminum, stainless steel, and titanium. It minimizes the waste and reduces overall production costs.

- Up to 20 microns

- 750W fiber laser

- Advanced cooling system to ensure consistent quality

- Ideal for intricate details and complex geometrics

- Best for industrial manufacturing mold and tools

XDM 2000

The XDM 2000 printer is a powerhouse with unmatched build volume and efficiency. Additionally, experts especially design this for industrial-scale applications. Therefore, it’s better for complex, high-quality, and large productions.

Nevertheless, it is good for generating defense tools and robust components. It brings innovation in metal printing technology with sustainability and control for quality assurance. The build volume of the XDM 2000 printer is 2000 x2000x 1000mm with up to 10 microns.

- Dual 1kWfiber lasers

- Advanced monitoring system

- Automated powder handling

- Massive build volume

- Dural laser system

- Helpful in defense, medical, automation, etc.

Summary of The Guide

In a nutshell, the write-up explains all the basics of 3D metal printing. Moreover, it explains the terms, pros, and applications. Also, it sheds light on the excellent quality of printing devices and explains their uses. Apart from this, the article explains the key features, benefits, and applications of all types of XDM printers. Lastly, ACS Material is the sole supplier of 3D metal printers, so you can visit them to buy them. Thank visiting coolcoder.org

More Stories

Using a Virtual Office for Your GST Registration

Hellstar Hoodie has become an iconic piece in

Why Should Consider Buying Dog Supplements